Midstream 101

What does midstream mean?

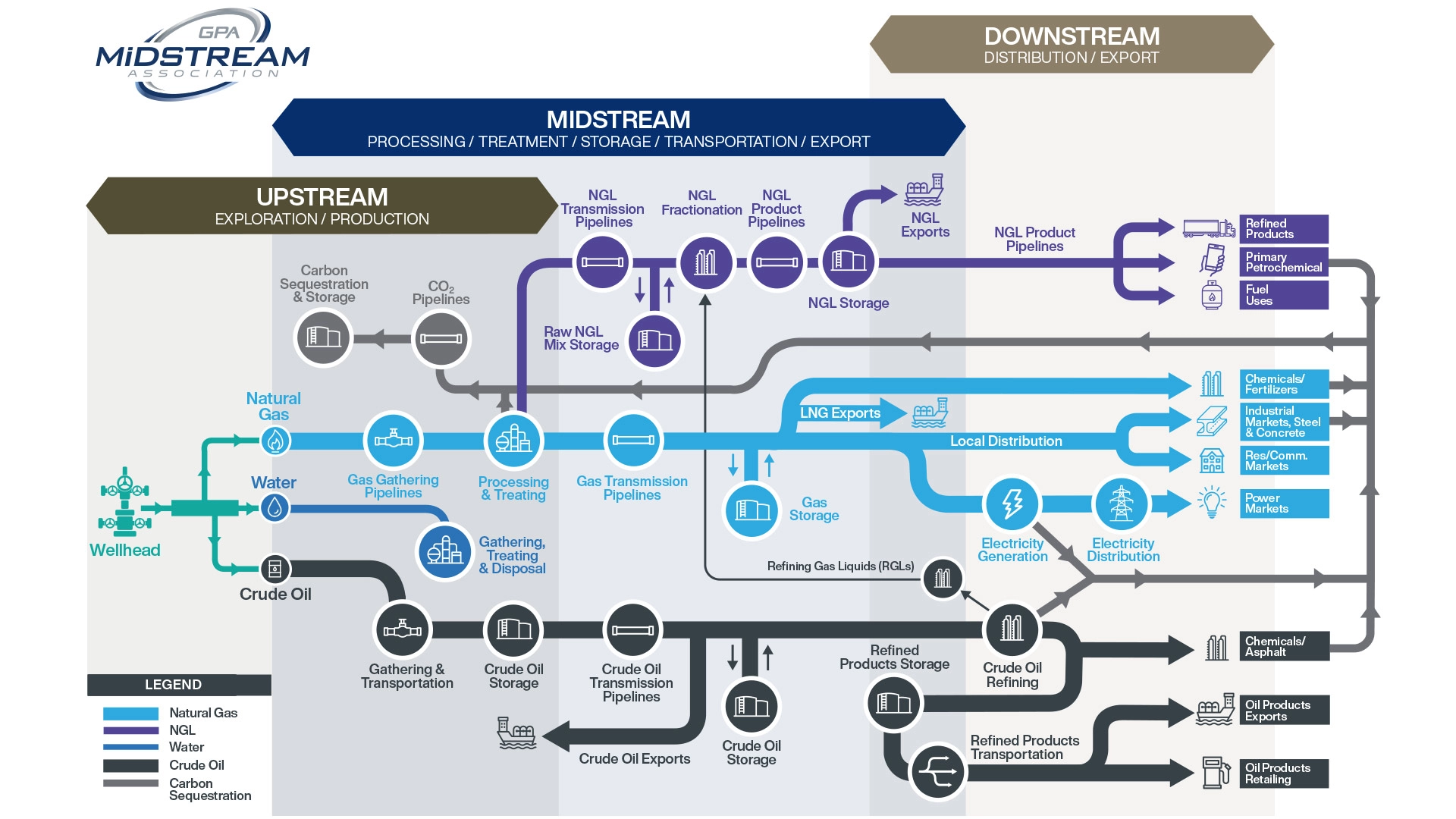

The oil and gas industry consists of three major segments: upstream, midstream and downstream.

What is midstream?

The oil and gas industry consists of three major segments: upstream, midstream and downstream.

- The UPSTREAM segment searches for oil and gas resources, drills and operates wells, and brings hydrocarbons to the surface.

- The MIDSTREAM segment connects upstream and downstream by gathering, processing, transporting, and storing natural gas, crude oil, and other energy products. Midstream includes all the infrastructure needed to gather raw resources, process them, and deliver them to the downstream segment, particularly including pipelines and processing plants.

- The DOWNSTREAM segment distributes energy to consumers and end users through products such as natural gas, propane, gasoline, kerosene, jet fuel, heating oil, lubricants, liquefied natural gas (LNG) and petrochemicals that are the feedstocks for many everyday items.

The midstream sector is a vital part of the North American oil and gas industry. After natural gas and crude oil are extracted from thousands of wells operated by the upstream sector, midstream companies gather the raw resources, process them and transport the processed materials to produce energy or for use as feedstocks to make consumer products like gasoline and plastics. Midstream “connects” the upstream and downstream energy segments efficiently and safely every day.

Why are pipelines the safest way to transport oil and gas?

According to the US Department of Transportation, pipelines are the safest way to transport crude oil, refined products, and natural gas over the long distances necessary to deliver energy to everyone who needs it. Pipeline capacity is far greater and more efficient than other modes of transportation. Midstream companies invest in technological advancements that significantly increase pipeline safety by monitoring operating conditions and product flows. Pipeline companies work with regulators to implement standards that ensure their systems reasonably and responsibly protect communities and the environment.

The Production Process

Upstream, Midstream, Downstream

Oil and gas industry supply chains are varied and complex. They start with in-ground resources, include processing, storage and transportation, and end with finished products enjoyed by consumers globally.

The steps from initial production to end-use can be divided into three major components: upstream, midstream, and downstream. Upstream refers to the exploration and extraction of natural gas and crude oil; midstream encompasses connection services such as gathering, processing, transportation, and storage; and downstream involves selling and distributing natural gas, crude oil, and natural gas liquids, as well as the transformation of petroleum feedstocks into everyday products. In some cases, sectors of the supply chain overlap. See graphic below.

Upstream: The Discovery and Production Process

The upstream sector is commonly known as the exploration and production (E&P) sector within the petroleum industry. It involves the extraction of crude oil and natural gas by using well-defined technical processes to safely drill wells and install in-ground production equipment that brings the valuable materials to the surface. After reaching the surface, equipment is installed to separate natural gas, crude oil, saltwater, and other impurities for further handling.

Significant activities in the upstream sector include:

- Geological and geophysical (G&G) surveying

- Searching for underground or offshore crude oil and natural gas reserves

- Obtaining leases and permissions from landowners to drill

- Drilling and completing wells

- Separating oil, saltwater, and gas at wellheads

- Short-term storage of the oil in producing areas

- Permanently sealing wells after the mineral reserves are depleted

Midstream: Gathering, Processing, Transportation, and Storage

Midstream gathering pipelines move or gather natural gas and crude oil production from thousands of wells to central locations for further handling. Natural gas is delivered to treatment plants where impurities are removed, as well as processing plants where valuable natural gas liquids (NGLs) such as ethane, propane, and butanes are extracted. The natural gas remaining after treating and processing is often referred to as “pipeline-quality natural gas,” which is transported via intrastate and interstate gas transmission pipelines to the downstream segment of the natural gas sector that fuels homes and businesses as well as electric power generators.

NGL transmission pipelines collect natural gas liquids from processing plants around the U.S. and deliver the mixture of NGLs to “fractionation centers.” The mixed NGLs are then separated into usable feedstocks, which are transported to petrochemical plants to transform them into consumer products such as plastics and medicines.

Midstream crude oil gathering pipelines operate separately from natural gas gathering pipelines to deliver oil to larger transmission pipelines that transport their products to U.S. refineries and export facilities.

Refiners turn the material into gasoline, diesel, and jet fuel.

Midstream companies also operate fleets of barges, rail cars, and trucks to deliver crude oil from supply area storage locations to consumer markets, as well as to move NGLs and crude oil refined products. Some stages of the midstream process may overlap with the upstream and downstream sectors.

Downstream: Distributing the Final Product

Downstream refers to the final stage of the oil and gas supply chain. This is where raw materials get turned into usable products and delivered to consumer markets. This includes refining crude oil and the marketing distribution of petroleum products such as lubricants, asphalt, jet fuel, diesel oil, heating oil, kerosene, and gasoline, as well as transformation of NGLs into petrochemicals used to produce plastics, medicines, medical equipment, paints, clothing and electronics. Natural gas is delivered to homes and businesses for heating. Industries like steelmakers and fertilizer manufacturers use natural gas and NGLs to grow crops, make food, produce consumer goods, and generate electric power to illuminate our living spaces and operate the information technology of modern life.

Significant activities in the downstream sector include:

- Distribution of natural gas to homes and businesses

- Generating electricity

- Crude oil refining

- Petrochemical processing

- Manufacturing consumer products

Midstream 101

Steps in Midstream Natural Gas Operation Value Chain

One of the oil and gas industry’s primary raw materials is natural gas, a fossil fuel and one of the world’s cleanest and most affordable and reliable energy sources.

The midstream sector has five main components in the movement of natural gas from its production location to its ultimate use: gathering, processing, storing, transporting, and marketing.

Midstream 101

The Importance of Midstream

The midstream sector is a vital part of the North American oil and gas industry.

After natural gas and crude oil are extracted from thousands of wells operated by the upstream sector, midstream companies gather the raw resources, process them and transport the processed materials to produce energy or be used as a feedstock to make consumer products like gasoline and plastics. Midstream “connects” the upstream and downstream energy segments efficiently and safely every day.

Midstream 101

Midstream’s Impact on the Environment

Midstream operators work with landowners, neighbors, regulators, and local and federal governments to plan pipeline routes and build facilities to minimize the impact on the environment and endangered species.

No matter the location, midstream assets are subject to numerous regulations and rules that ensure operational safety and environmental considerations are a top priority. When construction is over, regulations are in place that require companies to continuously monitor and measure midstream operations to ensure safe and reliable operations. These regulations provide strong incentives to apply and use best practices to minimize adverse impacts to the environment and local communities.

Industry is motivated to ensure its valuable products are contained within its systems so they can be purchased by its customers. In addition, midstream company employees want to prevent, reduce or mitigate the environmental impact of their operations on their families and communities in which they live.

Midstream 101

The Future of Midstream

Midstream facilities and services are an essential part of our energy future.

Changes in energy production to include more renewable sources can and should be done thoughtfully to ensure the United States does not lose the safe, affordable and reliable energy needed to power our economy and provide jobs for millions of people in manufacturing, services, and technology. Energy demands are growing, and diverse energy sources offer tradeoffs in affordability, reliability and sustainability to meet such demand.

Additionally, midstream is positioned to provide expertise in recovering and transporting carbon dioxide associated with carbon capture (CCUS) as well as the production and transportation of hydrogen and other liquid fuels in pipelines. The dedicated employees of U.S. midstream companies are committed to safely operating their facilities to deliver products to customers, and meet growing demand for energy while reducing the impact on the environment we all share.